PRE- ENGINEERED STEEL BUILDING

Pre-engineered building system, one of the fastest growing building systems in the industry has become the material of choice in building construction, compared to concrete structure. With a pre-engineered building system, your building are ready for use quickly and within your budget.

Pre-Engineered steel structure are built with primary members (frames), secondary structural members(roof purlins & wall girts), and outer cladding. The structural members are designed to be lighter in weight as well as high in strength.

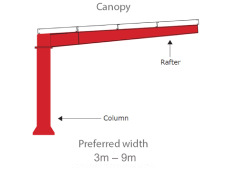

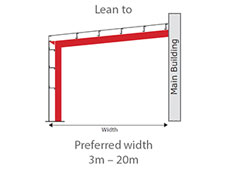

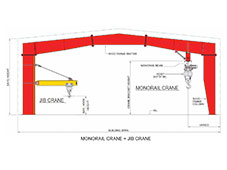

Additionally, Pre-Engineered Steel Buildings can be fitted with different structural add-ons like jack beams, mezzanine systems, crane systems, roof monitors, roof extensions, canopies, fascia’s, interior partitions and roof platforms depending on your requirements.

Cold formed Z and C shaped secondary structural members form the secondary, acting as supporting system for the external cladding.Roof purlins, wall girts, eave struts, C-sections, Flange braces, gable angles and base angles are used for secondary framing.

MK are able to supply mezzanine system, which is frequently used in industrial operations such as ware housing, distribution or manufacturing. If you are looking for in material handling efficiency and flexibility for manufacturing, maintenance operation and service shops MK can make the most of the space you have with a mezzanine system that has been designed to handle your load and material flow requirements.

The use of jack beams is an economical and safe approach for creating longer bay length when large unobstructed space is required. Common bay length (6. 7.5, 8, 9 and 10m) can be doubled with the use of jack beams making it possible to have 12, 15, 16, 18 and 20m clear bay length in areas where unobstructed space is required. In the example below the customer specified 16m bay lengths instead of the more economical 8m bay lengths. Jack beams were used in the interior of the building to make that possible. Jack beams may also be used on the exterior sidewalls in the same way.